Si-Factory

Si-Factory is a project carried out by Roltec in parallel with the thin-film photovoltaics project. We have launched the production of high-quality monocrystalline Intensive expansion, including a new production hall and line, has allowed for significant automation and a dramatic increase in production in 2024. We combine production with the direct implementation of photovoltaic farms.

The project, financed and implemented entirely by the company, primarily serves to meet the company's own energy needs. All production is directed directly to our installations. We have designed and implemented a complete solar farm system for all types of surfaces. We install our modules with the help of third-party contractors on flat roofs, pitched roofs, and ground-based roofs. We estimate the planned installations in the coming years at 40 MW. In 2025, we are implementing investments in the Greater Poland, Łódź, and Lower Silesian Voivodeships with a total capacity of nearly 15 MW.

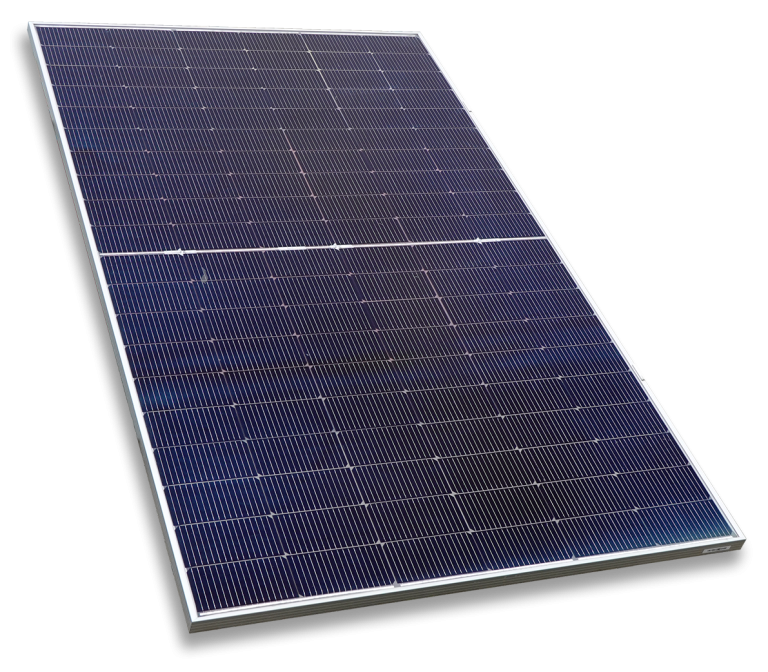

M10 Half Bifacial Module

Roltec Bifacial M10 modules are glass-foil modules protected by an aluminum frame. The active layer is located on two sides, allowing light to be absorbed from both sides (including light reflected from the substrate). The modules achieve peak efficiency up to 30% higher than single-sided PV modules (which depends primarily on the substrate's albedo). A refined production method guarantees a long module lifespan. It demonstrates significant resistance to mechanical damage, microcracks, salt mist, and ammonia.

Module type: BIJTHE-YYWWNNNN

- Power: 440 - 480 Wp

- Size: 1910x1135 mm

- Maximum efficiency: 22%

- Low operating temperature

- High mechanical resistance

Production technology

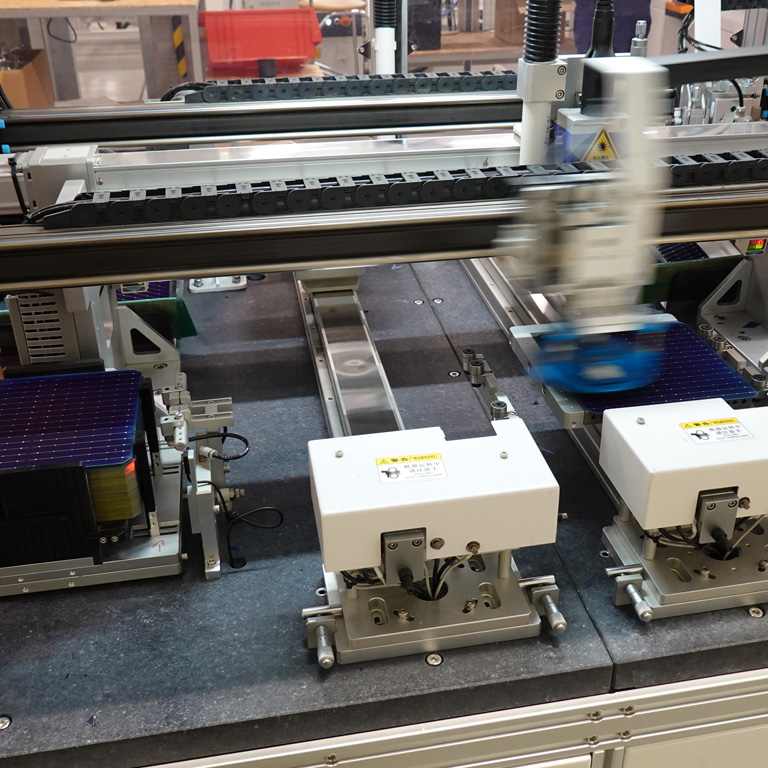

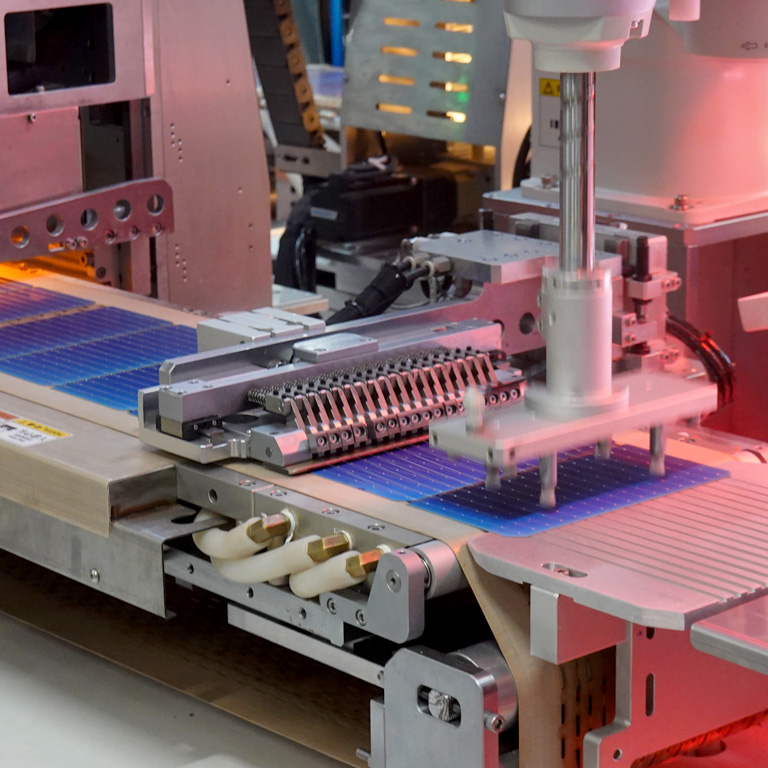

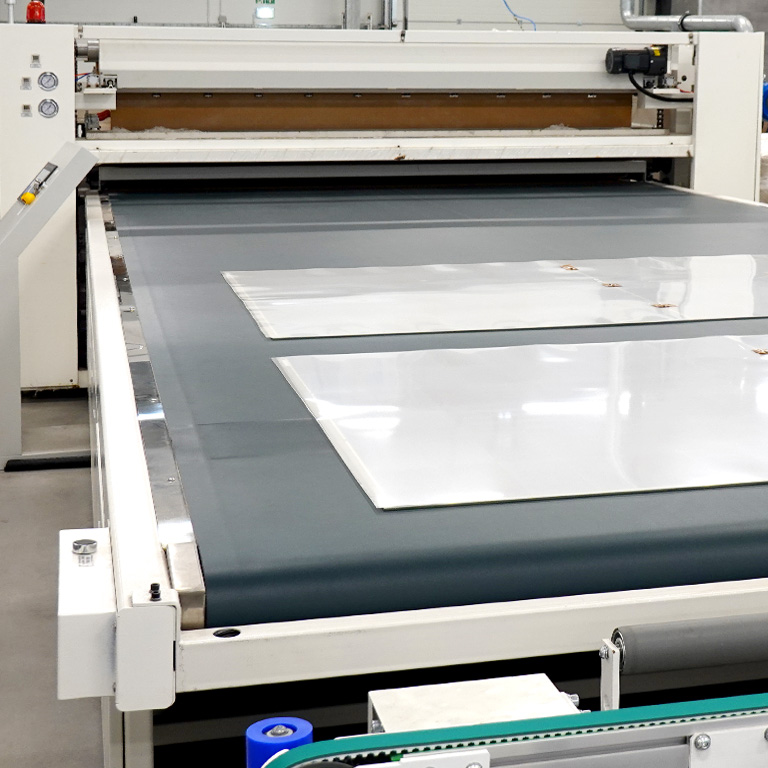

Monocrystalline silicon photovoltaic modules are manufactured on a partially automated production line, ensuring high quality and process repeatability. At the same time, our research and development department continuously works to improve the efficiency, quality, and durability of our modules.

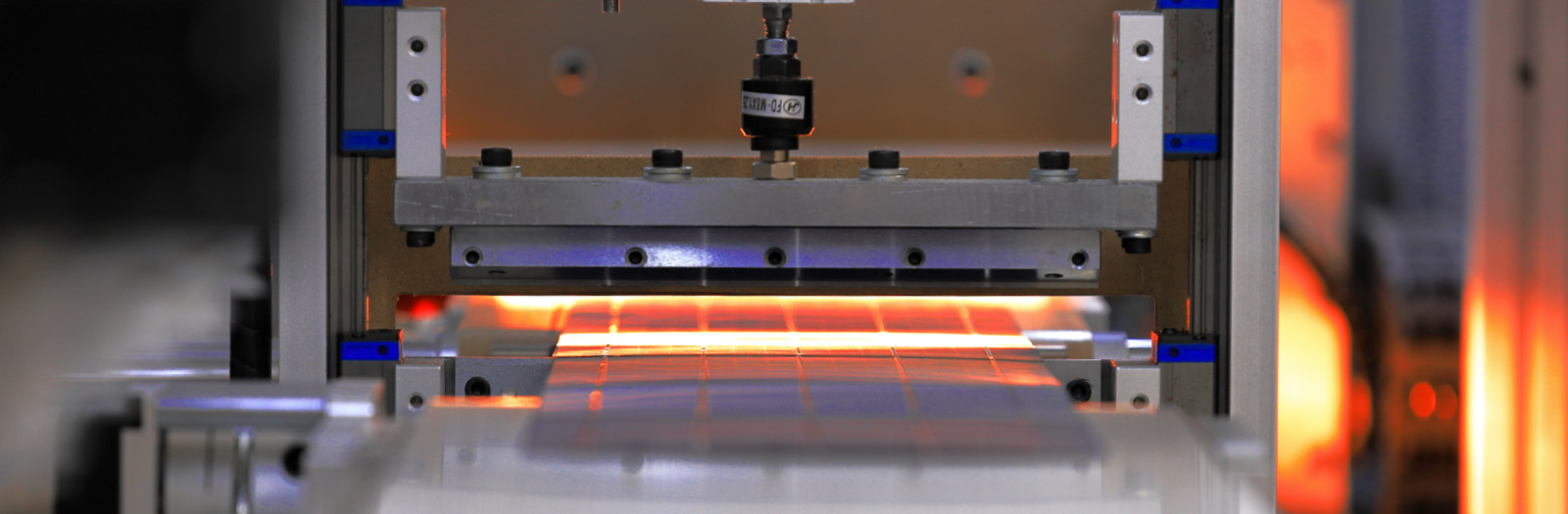

The first stage of photovoltaic module production involves connecting individual cells in series using connecting tapes. During an automated soldering process, a worker eliminates damaged cells. The connected cells are placed on glass covered with EVA foil and then electrically connected (soldered). After joining, additional layers of EVA foil and electrically insulating foil are applied, protecting the module from external factors. The prepared module is then laminated (in an oven) at approximately 140°C, where it is completely sealed (encapsulated). In the final stage, a junction box with cables is mounted to the module's bottom surface.

Finished photovoltaic modules are tested on a solar radiation simulator under standard test conditions (STC: 1000 W/m², 25°C, AM1.5G), where electrical parameters such as maximum power (Wp), short circuit current (Isc), and open circuit voltage (Voc) are determined. The modules meet all applicable standards for photovoltaic module design and safety (IEC61215, IEC61730, IEC63092, IEC TS 62941).

Si-Factory in numbers:

Our projects

We implement rooftop and ground-mounted photovoltaic installations using dedicated, proven components. Our comprehensive approach, from module production to farm construction, guarantees maximum reduction in kWh production costs.

The complete installation includes:

- G1 solar modules,

- supporting structure,

- inverters,

- wiring,

- electricity meters,

- monitoring application.