SOLAR FACTORY

Solar Factory project the implementation of Roltec's own new technology and the launch of a production line of high-efficiency thin-film photovoltaic cells based on it by applying and forming a CIGS layer using high-intensity light pulses.

PV technology (photovoltaic panels) has reached a level of readiness to revolutionize the power system, enabling consumers to produce energy for their own needs and transfer the surplus to the grid. Despite this, solutions that increase the efficiency of photovoltaic cells are still being sought. Second generation CIGS cells available on the market do not achieve 18% efficiency and module stability (90% efficiency after 10 years). The level of cell efficiency is the main need and also a market barrier.

The implementation of the new Roltec technology will allow already in 2025 to launch the production of cells with an efficiency of 18% , with reduced production costs and stability of the standard offered modules (90% efficiency after 10 years) compared to the previously known and offered market. 5

The SOLAR FACTORY project in numbers:

Patent application no. P.427122

ROLTEC INVENTION

We have improved the technology of applying the CIGS layer using vacuum methods (evaporation, magnetron sputtering and selenization/sulphurization).

A technological solution (invention) leads to a significant development of technology, including:

- Obtaining a better and controlled degree of crystallization of the CIGS layer - including control of the composition of crystals in the growth phase

- Obtaining a CIGS layer with lower roughness and larger grain size (crystalline domains)

- Possibility of applying crystals of various compositions (gradient cells) and a high degree of crystallization

- Thanks to the above, higher efficiencies of PV modules are achieved

- Reducing the time needed to produce the CIGS layer (in-situ and post-treatment)

- Lowering the temperature needed to form the CIGS layer - making it possible to carry out this process on flexible substrates.

- Lowering the temperature needed for selenization/sulphurization - making it possible to carry out this process on flexible substrates.

- Increase in employment in supported enterprises – 6.00 FTE;

- Number of process innovations introduced - 1 piece: new technology for the production of thin-film solar cells by applying and forming a CIGS layer using high-intensity light pulses.

- Number of introduced product innovations - 1 piece: thin-film solar cells with an efficiency of 18%, with reduced production costs and stability of standard modules (90% efficiency after 10 years).

- Number of non-technological innovations introduced - 1 item: marketing and organizational innovation introduced.

- Construction of a hall with an area of 1,650.00 m² - eligible amount PLN 1,975,600, total amount PLN 2,429,988.00

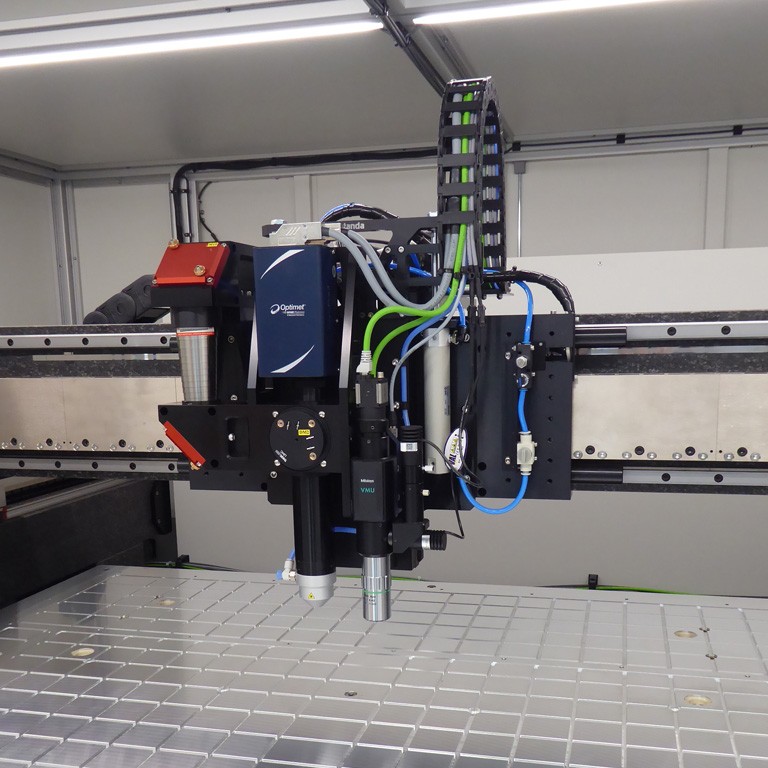

- Purchase of fixed assets (machinery, equipment, production hall equipment) 20 pcs. – qualifying amount PLN 8,604,400, total PLN 10,583,412

- Purchase of software for managing a production company 1 piece – qualifying amount

PLN 420,000, total PLN 516,600. - The total amount of eligible project expenses is: PLN 11,000,000.00.

- The total amount of total project expenses is: PLN 13,530,000.00.

As a result of the project, in 2022 new products will be introduced for the market and the company, i.e. photovoltaic cells with an efficiency of 18%, with reduced production costs and stability of the standard modules offered (90% efficiency after 10 years) compared to the previously known and offered ones. competitive cells on the market. The invention is covered by patent application No. P.427122.

- Number of enterprises receiving support - one

- Number of companies receiving subsidies - one

- Private investments supplementing public support for enterprises (grants) - PLN 8,580,000.00

- Number of enterprises supported to introduce products new to the market - one

- The number of enterprises supported to introduce products new to the company - one

- Number of purchased fixed assets - 20 pcs.

- Number of acquired intangible assets - 1 pc.

The investment is consistent with the assumptions:

- Strategy for smart, sustainable and inclusive growth Europe2020 - the project will influence the implementation of innovative solutions and increases the level of innovative investments in the EU. applicant , as a company from the SME sector, develops an industrial base, which increases the economic competitiveness of the region, national and European.

- Updated Development Strategy of the Wielkopolska Voivodeship until 2020 "Wielkopolska 2020" - one of the most promising industries is the production of machinery and equipment, the implementation of the project directly affects the implementation of the strategy's goals (goals 4.2, 6.1 and 6.5).

- Regional Innovation Strategy for Greater Poland for 2015–2020. The update (implementation) of the new technology that is the subject of the project fits into the areas of smart specialization "Industry of tomorrow".