CIGS panel factory

The subject of the project is the construction of an intelligent factory for thin-film photovoltaic panels along with an investment in technologies for the digitization and automation of production and management processes based on the concept of Industry 4.0.

The project includes the construction and commissioning of a photovoltaic panel production plant, including a production and warehouse hall with a technological annex and a social area, as well as an office building, along with land development and the necessary technical infrastructure, and the launch of production there (i.e. the installation of production lines, their integration, digitalization and robotization).

High-efficiency photovoltaic panels produced in the Wrocław factory will be a response to the growing demand of the renewable energy market. We want to fulfill our Mission to create a more sustainable future. We believe that our business and investment strategy will fit into the framework of the UN and EU Sustainable Development Policy, remaining a permanent basis for our approach to development and operational practices.

The target group for the solar modules produced at the factory will be households and enterprises developing PV installations.

Project in numbers:

The aim of the project is to build the first factory of thin-film photovoltaic panels using CIGS technology in Poland in Wrocław, where it will be possible to launch an automatic and integrated technological line according to the technology developed by the Applicant, enabling the high-efficiency production of CIGS photovoltaic cells with an average efficiency of 15%.

The project includes 2 tasks:

Task 1: "Construction of a production hall with a warehouse, social area and technological annex."

The hall's footprint is 13,826.36 m², divided into four sections: the production line, warehouse, staff facilities, and a technological annex.

Number of floors:

a) Part with the production line – one floor,

b) Warehouse part – one floor,

c) Social part – three floors,

d) Part of the technological annex – three floors.

Task 2: "Delivery and installation of line elements, integration and implementation of digitalization and robotization solutions, and production launch."

The task includes acceptance of works, delivery, installation of all components of the technological line for integration in the constructed production plant, optimization and launch of production according to the developed technology covering the following process stages:

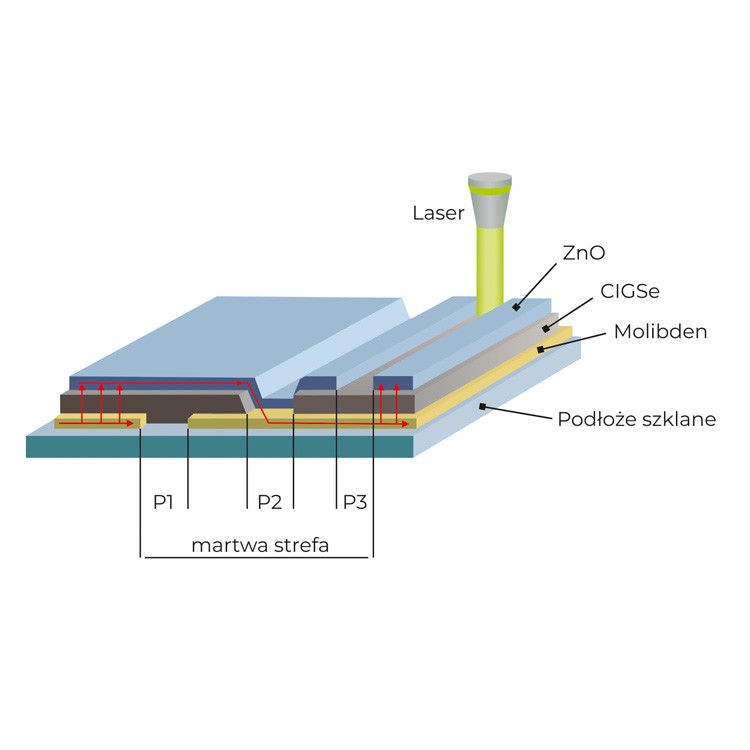

- applying thin layers using vacuum methods,

- laser and mechanical structuring,

- chemical bath used to deposit a thin (30–60 nm) layer of cadmium sulphide CdS,

- cutting and sanding the edges of the modules before integration,

- installation of busbars, cabling and lamination of the front safety glass,

- measurement of PV module parameters using a sun simulator,

- testing PV module defects using electroluminescence,

- encapsulation of modules by lamination (glass or EVA foil), filling technical holes with resins, sealing with silicone,

- electrical measurements of finished modules using a sun simulator,

- final assembly,

- labeling, sorting according to measured performance and packaging of finished modules,

- collection of the finished product and storage.

The entire process will be supported by production media installations (located in the technological annex), in particular installations for: process chemistry, wastewater and process gas treatment, preparation of demineralized water, compressed air, ventilation, and chilled water.

The project will include expenditures on fixed assets for all installations and machinery necessary to implement the entire process according to the assumed parameters within the entire system, including environmental aspects.

Expenditures in this area include:

- Glass cutting line - 1 pc.

- Wastewater and degassing treatment installation - 1 pc.

- Softened and ultrapure water treatment plant - 1 pc.

- Natural gas boiler room – 1 pc. (non-eligible cost).

- Chilled water station (consisting of 3 cooling production systems) — 1 pc.

- Air handling units (production hall) — 1 set

- Air handling units (technology annex) - 1 set.

- Air conditioning units - 1 set

- Compressor room - 1 set

- Power generator - 1 pc.

- Complete photovoltaic installation (non-eligible cost).

Based on the installed line, installation and constructed facility, installation, integration and launch of digital solutions will be carried out by incurring expenses in the following areas:

- purchase of servers, tape libraries, arrays, FC switches - 1 set

- purchase of LAN network - 1 set

- purchase of a monitoring system, remote access (IPC, VPN) - hardware - 1 set

- office equipment (computers, printers) — 1 set

- IT installations: BMS — production hall with warehouse, technological annex, social parts (low-current installations).

- ERP + MES system,

- Monitoring, remote access (configuration, commissioning).

- Servers for network maintenance, IT security, firewalls.

- Material Flow Control System.

- Support for the SCADA system.

Digital results:

- introducing innovative solutions aimed at digitizing business processes (management, operational, auxiliary);

- using artificial intelligence (AI) to manage business processes,

- implementation of dedicated systems that automate processes in the area of digital security,

- the use of robotics and operational technologies,

- use of Machine to Machine communication technology (M2M0) and the industrial Internet of Things.

The implementation of the project ensures long-term effects that exceed the duration of the instrument, among others due to the fact that the construction of a smart production plant in line with the Industry 4.0 concept and the implementation of activities aimed at digital transformation contribute to accelerating economic recovery after the pandemic and strengthens the long-term potential for economic growth.

The photovoltaic panel production business aligns directly with long-term global market trends related to the green transition. Photovoltaics is a key source of renewable energy in the context of the pursuit of climate neutrality under the EU's "Ready for 55" programs and the "Renewable Energy Directive." The project's results have the potential to transform the market, as customers can more widely use more efficient and cost-effective CIGS modules.

The project's effects will be sustained beyond the development plan's eligibility deadline of August 31, 2026. The project is scheduled for completion by December 31, 2025, after which mass production will commence. The project's results are expected to have an impact of at least 10 years, driven by factors including the useful life of the infrastructure created and the profitability of meeting demand for these types of products.

Product indicators:

- Constructed hall area (factory) – 13,826.00 m².

- Number of implemented IT solutions in the field of business process digitization, including the use of artificial intelligence – 1 pc.

- Number of purchased fixed assets in connection with building installations for the implementation of digitalization solutions and Industry 4.0 technologies – 10 pcs.

- The capacity of the photovoltaic installation installed in the facility is 0.63 MW.

Outcome indicators:

- Enterprises covered by support (including: small, micro, medium and large) – 1 enterprise.

- Creation of new specialist jobs – 17.00 FTE.

- Reduction of environmental emissions and reduction of energy emissions – 240.80 kWh/m2 per year.

- Increase in production capacity – 50 MWp per year.

- Average efficiency of produced CIGS modules – 15.00%.

CIGS technology

Durability, effective operation and aesthetics make CIGS conquer the construction and construction market. Thin-film photovoltaic technologies practically use photovoltaics in urban space and landscape architecture (facade panels), creating ecological integrated BIPV (Building-integrated Photovoltaics) and BAPV (Building-attached Photovoltaics) solutions.

Thanks to high absorption even in low light and low temperature coefficient, CIGS modules are characterized by high efficiency even in difficult conditions. Non-toxic and safe cells are 98% recyclable. Roltec modules will be used primarily in traditional energy for enterprises (photovoltaic farms).

Aesthetic, frameless modules ensure stable energy production

Copper Indium Gallium and Selenide, or CIGS, is a technology of thin solar cells (photovoltaic) based on the deposition of four elements (copper, indium, gallium, selenium) on any substrate. What distinguishes it from many other technologies is the best spectral response, i.e. radiation absorption. The great advantage of our technology is its high efficiency while using a small amount of material.